What’s the Best Method for Installing an Oil Pressure Gauge in a Classic Mini Cooper?

Classic Mini Coopers are endearing vehicles, packed with character and timeless appeal. However, these vintage machines require careful monitoring and maintenance to ensure optimal performance. One crucial aspect to keep tabs on is the engine oil pressure. Installing an oil pressure gauge can provide you with accurate, real-time information and help you avoid serious engine damage.

Choosing the Right Oil Pressure Gauge

The first step in the process concerns the choice of your oil pressure gauge. A variety of gauges exist on the market, each designed to meet specific needs. You might consider an electrical gauge for simplicity and ease of installation. Alternatively, a mechanical gauge may suit those who prefer a more hands-on, traditional approach.

In parallel : What Are the Best Techniques for Enhancing Sound Deadening in a Luxury SUV?

When deciding, keep in mind that your chosen gauge should match your Mini Cooper’s aesthetic. Look for a gauge with a similar style and finish to your car’s dashboard. In essence, your goal is a gauge that not only works well but also looks the part.

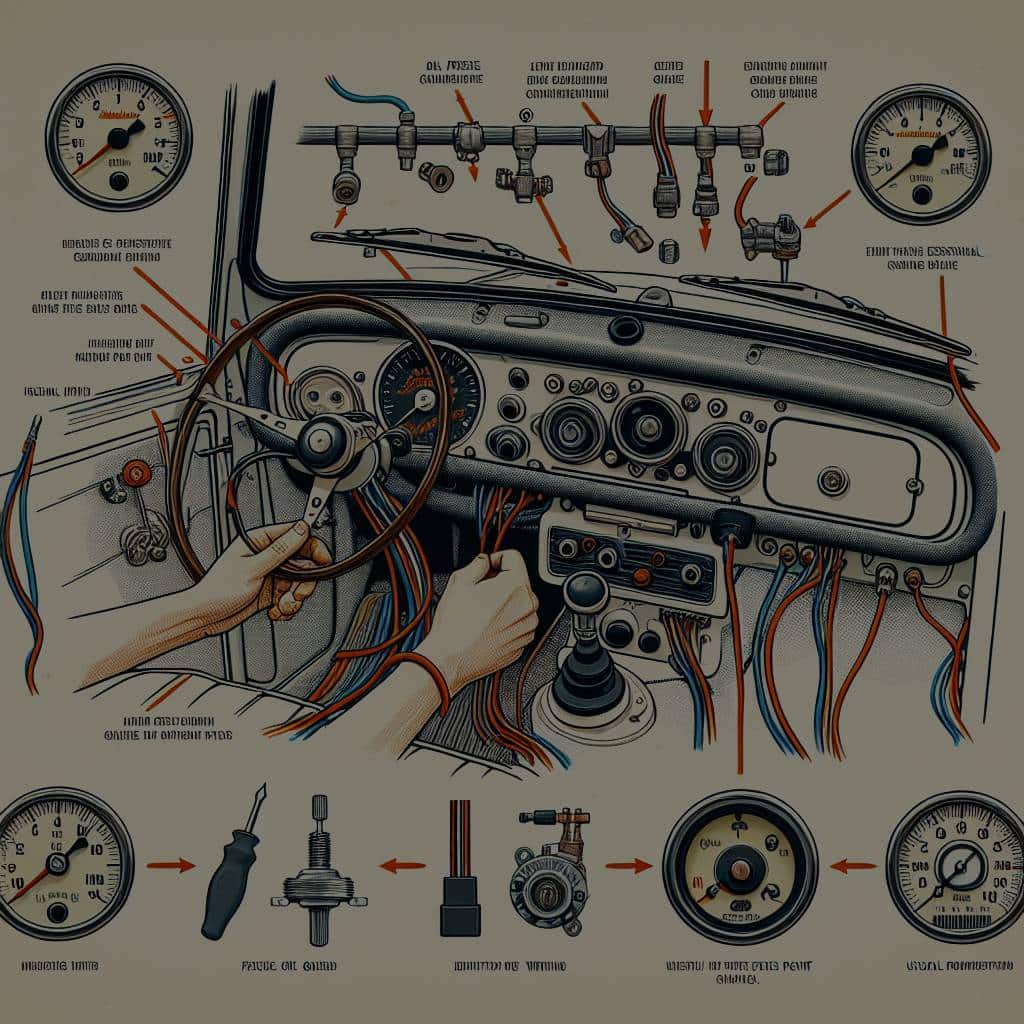

Preparing the Necessary Tools

Before you get started, gather the necessary tools. This includes a wrench set, an electrical wire, a sender unit, a thread tape, and an oil pressure gauge. For the sender, a sensor switch is ideal as it provides the most accurate readings. The thread tape is to ensure a watertight seal, preventing oil leaks.

In the same genre : Can You Improve Throttle Response with a Drive-By-Wire Throttle Controller in a Toyota 86?

To install the gauge, you will also need a tap. This tool creates the threads needed to screw in your sender. And, of course, be sure you have a good-quality oil pressure gauge. The sender and the gauge should be compatible, so check this before purchasing.

Locating Your Pressure Sender

The location of your pressure sender will be unique to your Mini Cooper model. In most Mini Coopers, the sender is typically found towards the back of the engine. It will usually be a round, cylindrical part with a wire post coming out of the top. Once you have found it, carefully remove the original sender by disconnecting the wire post and unscrewing the sender.

For this task, use an appropriate-sized wrench and proceed with care. Remember, these parts can be tight and brittle due to the engine heat and the age of the vehicle. Thus, gentleness is key to avoid damaging any components.

Installing the Oil Pressure Gauge Sender

Before installing your new sender, prep the threads with thread tape. This step is crucial as it helps create a tight, leak-free seal. Now, carefully screw in the new sender into the location of the old one.

Once the sender is securely in place, connect the electrical wire to the post on the sender. Ensure this connection is secure as it carries the signal from the sender to the gauge. A loose or poor connection here can lead to inaccurate readings on the gauge.

Mounting the Oil Pressure Gauge

The final step in this process is mounting the oil pressure gauge. This step will vary greatly depending on the type of gauge you’ve chosen. Most gauges will come with detailed mounting instructions, so be sure to follow them closely.

In general, you will want to find a location on your dashboard that is easily visible and accessible, but doesn’t obstruct your view or interfere with any other controls. After you’ve selected the perfect spot, secure the gauge. Connect the other end of the electrical wire to the gauge.

Once everything is in place, start your Mini Cooper and monitor the oil pressure readings on the gauge. The readings should stabilize once the engine has warmed up. If the readings are erratic or show extremely high or low pressure, recheck all your connections and the installation of the sender.

Keep in mind, though, that the well-being of your beloved Mini Cooper depends on accurate oil pressure readings. Therefore, if you encounter any troubles during the installation process or are unsure about any steps, it’s wise to consult with a professional. After all, with a classic car like a Mini Cooper, getting things done right is of utmost importance.

And there you have it. Take a step back and admire your newly installed oil pressure gauge. Now you can hop into your Classic Mini Cooper with the confidence of knowing exactly what’s happening in your engine. Safe and enjoyable motoring awaits.

Troubleshooting Your Oil Pressure Gauge

Now that your oil pressure gauge is installed, it is crucial to understand what could potentially go wrong and how to address it. The first red flag would be an erratic gauge, with the pressure readings fluctuating wildly. The other possible issue would be a continuous low oil pressure reading. Both of these problems can point out to potentially serious issues with the engine or the new gauge install.

Firstly, inspect the engine block to see if there is any leakage of engine oil. If there is indeed a leak, it could be related to the pressure sender or the thread sealant used during installation. Make sure that the pressure sender is properly screwed into the engine block, and additionally, confirm if the thread sealant (thread tape) is sufficiently applied to form a watertight seal.

Next, verify the connections between the pressure sensor, the pressure switch, and the gauge. Any loose wire can lead to inconsistent readings. Also, cross-check the compatibility between the pressure sensor and the gauge, as incompatible parts could result in faulty readings.

Furthermore, if your Mini Cooper has an ‘idiot light’ or warning light for low oil pressure, and it’s still lit even though the new gauge shows normal pressure, it could indicate a problem with the wiring or the sensor engine.

Moreover, don’t forget to check the condition of the engine coolant. Overheating can cause the oil to thin and consequently lower the oil pressure.

Should you encounter any persistent issue, it’s best to consult a professional mechanic. A misdiagnosed problem or improper gauge install can lead to severe engine damage.

Conclusion: Enjoy Your Ride and Stay Informed

Installing an oil pressure gauge in your Classic Mini Cooper is a wise and beneficial investment. This addition will provide you with real-time data about your engine’s health, helping prevent potential damage due to low oil pressure. The process, from selecting the right gauge and tools to locating the sender and mounting the gauge, is quite straightforward if you follow the steps carefully.

With the gauge installed, remember to consistently monitor your oil pressure as you drive. Know what’s normal for your Mini Cooper. Generally, the pressure should stabilize once the engine is warm. However, if you notice constant low oil or fluctuating pressure, immediately inspect the gauge install, connections, and the engine itself.

And finally, remember to enjoy the ride. The Classic Mini Cooper is a vehicle that embodies the joy of driving. With the appropriate attention to maintenance and the addition of helpful tools like an oil pressure gauge, you can continue to experience that joy for many more miles down the road.

Note: Always remember, safety is paramount. If in doubt, consult a professional mechanic to avoid damaging your precious Mini Cooper. Happy motoring!